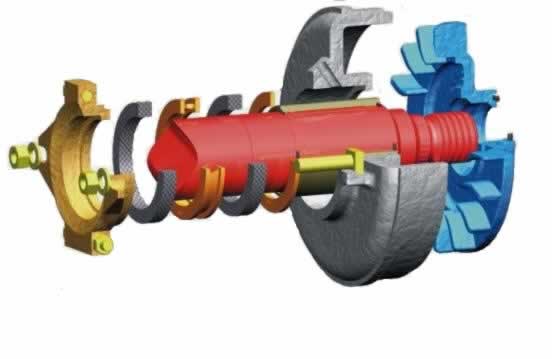

Expeller Seal

EXPELLER SEALING

Expeller seals are designed to reduce bypass pressure from the pump into the gland or rotary sealing area of the pump. This is achieved through a combination of centrifugal force and component tolerances.

Expeller seals rely on pump speed and the tolerance between the housing and expeller face to maintain performance. One of the main drawbacks of expeller sealing is the compromise that needs to be made between pump performance and sealing performance.

In most typical slurry pumps you can either adjust the pump impeller forwards for reduced internal recirculation and improved efficiency at the impeller end which will result in reduced expeller performance as it opens the sealing face gap. Or you can adjust the impeller backwards for better expeller performance.

Once you have the right balance the pump generally gives reasonable performance for both the wet end and sealing end. However depending on materials used for the expeller ring the sealing performance can deteriorate rapidly. As the Expeller Ring (housing that the expeller runs in) wears it creates turbulent flow patterns and increased tolerances which reduce the effectiveness of the expeller itself and also leads to accelerated expeller wear. Pumping a wearing medium the expeller sealing area is continually subjected to wear which will lead to it’s eventual failure.

As with Gland seals most expeller seals have an outboard seal for when the pump is stationary as the expeller only works when operational. This is usually a gland seal with reduced packing rings or alternatively with V-ring seals. As per gland sealing many of the same considerations need to be made when selection and supporting this type of sealing device.

Slurrytech have recognised the shortfall in expeller seal design and have and can develop customised solutions to enhance expeller seal life and performance.

EXP-WRC - This is a standard expeller seal which has been modified to take an internal coating of Wear Resist Compound (WRC). this design is currently being used at many Mineral Sands operations and is being trialled at gold mines.

Benefits – Increased wear life, maintaining of expeller performance, maintaining of expeller geometry due to reduced attrition and wear of expeller ring, easy to rebuild and repair with additional WRC, reduced waste, lower costs. When fitted with Ceramax wet end parts pump and seal life is significantly increased.

Drawbacks – None noted.

EXP-SiC - This is a standard expeller seal which has been modified to take a Silicon Carbide internal lining. This design is currently being used at some Mineral Sands operations.

Benefits – Significantly increased wear life over standard materials, increased wear life over WRC expeller ring, maintaining of expeller performance, maintaining of expeller geometry due to reduced attrition and wear of expeller ring, can be rebuild, reduced waste, lower life costs. When fitted with Ceramax wet end parts pump and seal life is significantly increased.

Drawbacks – Higher initial cost.

Winclan factory

We enjoy strong technological power, excellent equipments and perfect inspection instruments, so we could provide you high-quality products with competitive price.